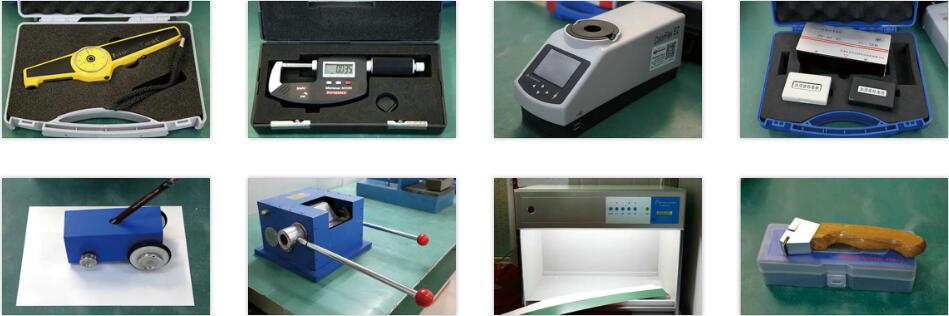

We have our own Physical & Chemical Testing Center Lab. to guarantee our product quality. Our test items & instrument fully meet international standards.

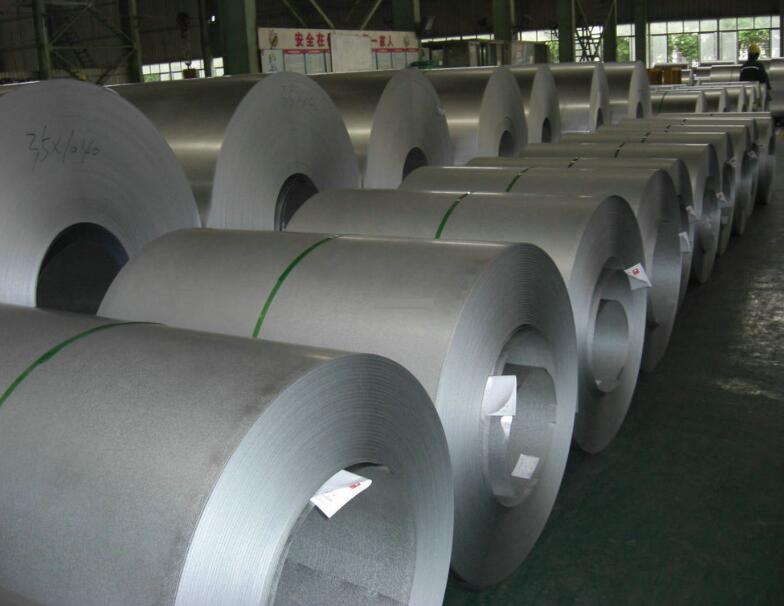

Packing Details

Standard Export Packing:

4 eye bands and 4 circumferential bands in steel

Galvanized metal fluted rings on inner and outer edges

Galvanized metal and waterproof paper wall protection disk

Galvanized metal and waterproof paper around circumference and bore protection

About the sea worthy packaging: extra reinforcement before shipment to ensure that the goods are safer and less damaged to customers.

More to Learn about Galvalume Steel.

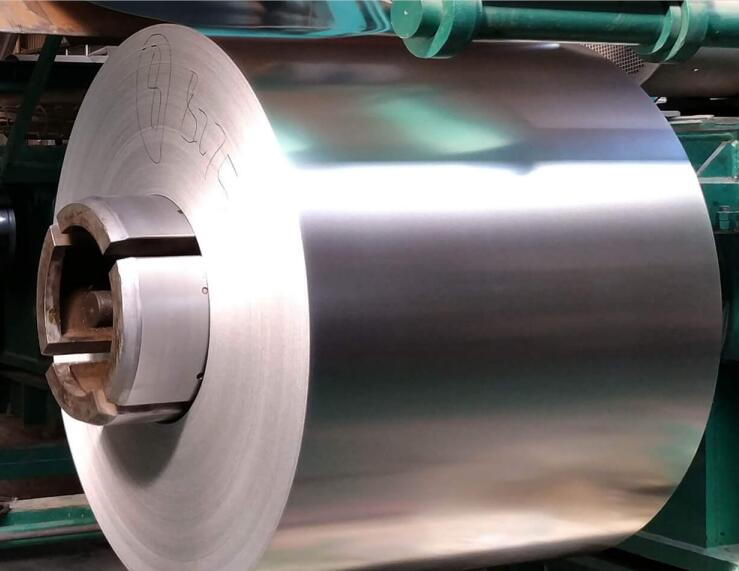

What is Galvalume Steel?

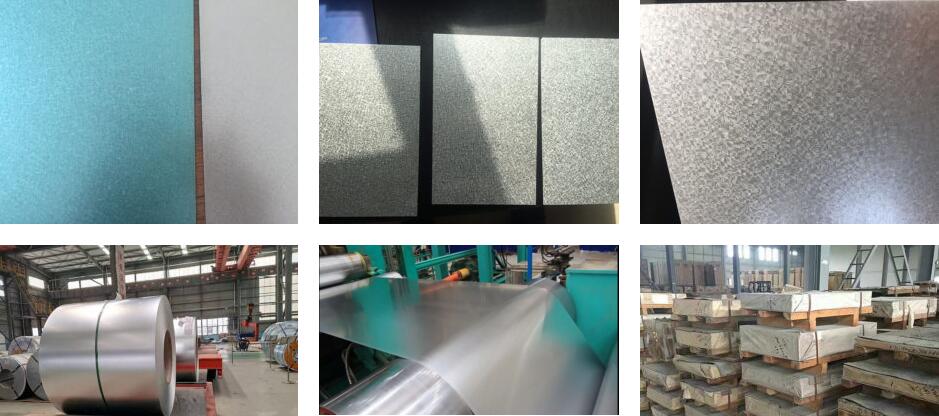

The hot-dip galvalume steel sheet is made by a kind of cold-rolled steel coil with different strength and thickness specifications as the base metal which is pre-coated by hot-plating for Al-Zn coatings on both sides and has a mass percentage of about 55% 43.5% zinc, 1.5% Si, combined with physical protection and integration of high durability and electrochemical protection features of Al and Zn to obtain the substrate metal’s strength and ductility but also corrosion resistance of the coating.It not only can protect the inner metal base from corrosion but also the surface was highly decorative bright silver gray and the regular spangle and has a bumpy sense. And this Aluzinc layers coating has very good corrosion resistance ability which offers it 2-6 times the life span versus galvanized steel coils. Developed from hot dipped zinc galvanized and hot-dipped aluminum galvanization tech, galvalume steel combines with excellent characteristics of both products, premium corrosion and oxidation resistance of hot dipped aluminum galvanization and exceptional electrochemical properties of hot dipped zinc coated galvanization, which gives galvalume steel strong anti-rust and anti-corrosion ability at the edge and on the scratched surface. The corrosion resistance property of the 55% aluminum zinc steel roll is from the aluminum layer barrier protection function and the sacrificial protection function of zinc layer. When the steel roll happens trimming, scratches and abrasions, the zinc will take the role of sacrificial coatings to protect the steel’s anti-corrosion, the aluminum will form an oxide insoluble protection barrier layer. Aluminum zinc alloy steel coil has been in a variety of different atmospheric environment, carried out more than 20 years of outdoor exposure test, it is confirmed that 55% galvanized steel roll trimming protection function is better than galvanized steel and 5% aluminum zinc steel.

Hot Dip Galvalume Steel Coils Equivalent Standards

| Q/BQB 425-2004 | AS 1379-2001 | EN 10215-1995 | ASTM A792M-02 | JIS G3321:1998 | ISO 9364-2001 |

| DC51D+AZ | G2+AZ | DX51D+AZ | DX51D+AZ | SGLCC | 1 |

| DC52D+AZ | G3+AZ | DX52D+AZ | DX52D+AZ | SGLCD | 1 |

| S250GD+AZ | G250+AZ | S250GD+AZ | S250GD+AZ | – | 250 |

| S300GD+AZ | G300+AZ | – | – | – | – |

| S350GD+AZ | G350+AZ | S350GD+AZ | S350GD+AZ | SGLC490 | 350 |

| S550GD+AZ | G550+AZ | S550GD+AZ | S550GD+AZ | SGLC570 | 550 |

Zinc & Galvanizing Coating Type

| Zinc & Galvanizing Layer Type | Aluzinc & Galvalume Coatings | AZ |

| Zinc & Galvanizing Layer Weight (g/m²) | 30/30, 40/40, 50/50, 60/60, 75/75, 90/90 |

Galvalume Steel Surface Structure Type

| Item | Type | Characteristic | |

| Surface Structure | Reuglar Spangle | N | Spangle shaped by galvalume coating condensation after galvanization |

| Polished Spangle | S | Regular spangle processed through polishing to get the surface structure |

Aluzinc Steel Coil Surface Treatment Types

| Item | Surface Treatment Types | Remarks |

| Item | Chromated passivation | Chromated passivation could deduct black rust while in transportation or stockie |

| Oiled | Oiled surface treatment could deduct black rust, but not the oil used for afterwards machining rolling and punching lubricant oil | |

| Chromated passivation+Oiled | Chromated passivation plus oiled surface treatment could help duduct black rust more. | |

| Anti Finger Print Film | Anti finger print film surface treatment could help duduct black rust more. | |

| Non-Treatment | If non surface treatment, steel coils could easily to happan with black rust, it due to cautious to buy for clients. |

Galvalume Steel Grade

| Galvalume Steel Coils Grade | |||

| Steel Grade | EN 10215 | ASTM A792M | JIS G3312 |

| Galvalume Steel for Cold Forming and Deep Drawing | DX51D+AZ | CS Type B/C | SGLCC |

| DX52D+AZ | DS Type | SGLCD | |

| Galvalume Structural Steel | S250GD+AZ | 255 | – |

| – | – | – | |

| S350GD+AZ | 345 Class 1 | SGLC490 | |

| S550GD+AZ | 550 | SGLC570 |

Main Advantage of Galvalume Steel.

1. More fluent and smoother surface and superior corrosion resistance property than hot dipped zinc galvanized steel coils.

2. Excellent heat resistance durable ability and anti-oxidation performance. It can bear temperature under 315℃ without tarnish and can be applied normally under 500℃ for long period. They could reject erosion from water and mud. They are the ideal steel materials for water heating machines, food dehydrators, exhausted tubes, automobile mufflers. And its heat reflection ratio is more than 75% which is double of zinc coated galvanized steel. Heat resistance of the 55% aluminum-zinc alloy steel plate is better than that of the galvanized steel sheet, similar to the high-temperature oxidation resistance of the aluminum plate.

3. Excellent performance for coating and machinability. It is highly adhesive to organic color pre painted coatings, and it could be welded and processed as the zinc galvanized steel metals. And it could be cold bent and punching while getting beautiful outlooks. It is also cost savings as a smaller amount of base metal consuming for the same thickness, as aluminum is lighter than zinc density. It also usually gets PVDF resin to get superior chalk resistance and gloss retention as well as stain and chemical resistance. This PVDF (Poly Vinyl Irene Fluoride) is softer than polyester, making it highly formable without risk of cracking. This pretreatments and primers along with superior paint coating have increased product warranties dramatically.

Industrial Applications.

Since galvalume steel coil is manufactured using the best possible raw materials, it is used in numerous types of industries, which include:

–Petrochemical

–Paper

–Construction

–Mechanical Engineering

Having a compact design and elevated strength and durability, this coil is put through numerous tests to ensure it can meet various industry standards. Specific application for galvalume steel coil are: Automotive Mufflers, Roofing and siding usage, Furniture, Appliances like food dehydrators, tubes, computer cases, exhausted gutters. structural sections, composite panels, microwave, washing machine, refrigerators, etc.

Color-Coated Coils.

One of the biggest benefits of galvalume steel coil is that much of it comes in color-coated assortments, making it a very versatile industrial material. For example, when used in marine and industrial projects, the corrosion rate of color-coated coil is up to four times better than other types of coil. And when this coil is used in roofing applications, it has an exceptionally long life, often lasting well over 30 years before even the most minor maintenance is needed.

Temperature Resistance.

Since galvalume steel coil is used in numerous applications where the environment may have extremes in temperature, humidity, and other factors, it’s been tested to make sure it can resist extremely high temperatures when used in virtually any type of application. With most types of galvalume steel coil, testing has shown it can resist temperatures as high as 599 degrees Fahrenheit without experiencing surface damage or discoloration, resulting in excellent paint adhesion.

Other Uses

Along with being used for roofing, marine, and other industrial applications, this coil is also able to be used in many other ways as well. Because it adheres so well to paint and resists corrosion, it has in recent years been used in home electrical appliances and buildings, showcasing its versatility. Possessing an iron-zinc alloy layer that makes it highly workable, it can be used in appliances that are smaller and smaller. Because of this, it’s viewed by many within mechanical engineering as an all-purpose material.

Take Advantage of the Versatility.

Whether you are a mechanical engineer, construction project engineer, or another industry professional, it’s clear this type of steel coil has many uses that make it versatile as well as cost-effective. To ensure your company is saving money while also using the best possible materials, contact a steel coil supplier today and discuss its many benefits.

Application.

Architecture: Roofing, External Siding, Garage, Barrier, Shutter

Household Appliances: Oven, Explosion Proof Steel Strip, Air-Condition System Covering, Solar Heating, Electrical Unit

Automobile: Mobile Muffler, Vent Pipe, Catalysis Converter Heat Shield, Bottom Accessories

Industrial Instrument: Electric Controlled Cabinet, Industrial Refrigerator, Vending Machine.