304 321 316L 310S 904L

| Availability: | |

|---|---|

| Quantity: | |

Product Description

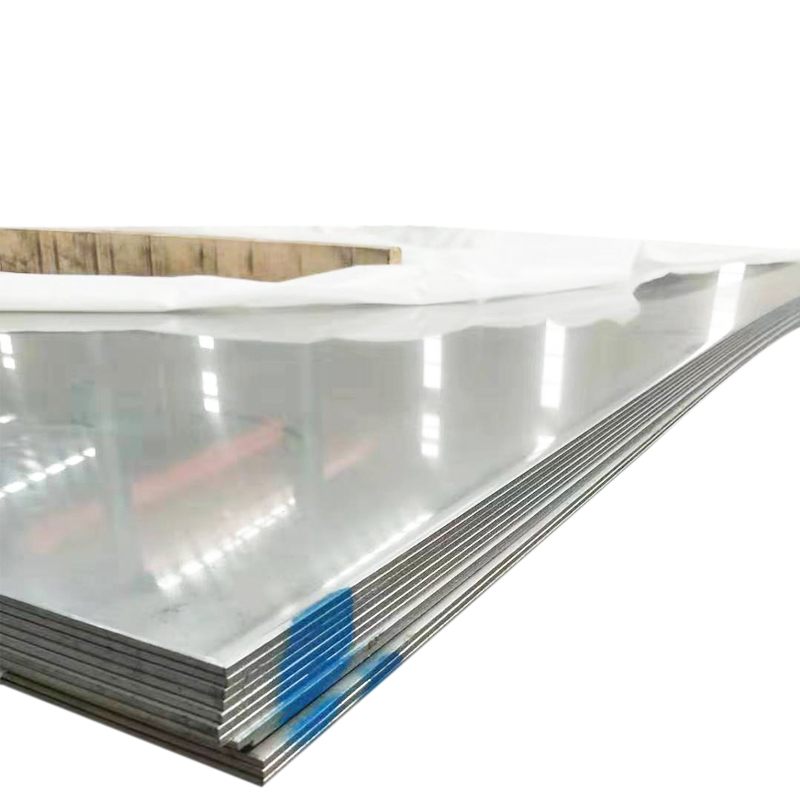

SS 304 316 316L 309 310 310S Stainless steel plate

The surface of the stainless steel plate is smooth and has high plasticity, toughness and mechanical strength,and is resistant to corrosion by acids, alkaline gases, solutions and other media. It is an alloy steel that does not easily rust, but it is not absolutely not rusty. Stainless steel plate refers to a steel plate that is resistant to corrosion by weak media such as atmosphere, steam,and water, and acid-resistant steel plate refers to a steel plate that is resistant to corrosion by chemically aggressive media such as acid, alkali, and salt. Stainless steel plates have been around since the beginning of the 20th century, and now have a history of more than a century.

2. Performance

Corrosion resistance

The stainless steel plate has the ability to resist general corrosion similar to the unstable nickel-chromium alloy 304. Long-term heating in the temperature range of chromium carbide may affect alloys 321 and 347 in harsh corrosive media. Mainly used in high temperature applications, which require strong anti-sensitization properties to prevent intergranular corrosion at lower temperatures.

High temperature oxidation resistance

Stainless steel plates have high temperature oxidation resistance, but the oxidation rate will be affected by inherent factors such as exposure environment and product form.

Physical properties

In addition to the thermal conductivity of the metal, the total heat transfer coefficient of the metal also depends on other factors.

In most cases, the film heat dissipation coefficient, rust and metal surface conditions.

Stainless steel can keep the surface clean, so its heat transfer is better than other metals with higher thermal conductivity.

Technical Standards for Stainless Steel Plates High-strength stainless steel plates with excellent corrosion resistance, bending performance, and toughness of welded parts, as well as excellent stamping performance of welded parts, and methods of manufacturing the same.

3. Surface finish Characteristics and application

NO.2B

The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses.

NO.3

Polished with abrasive belt of git#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc.

NO.4

Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc.

HL

Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc.

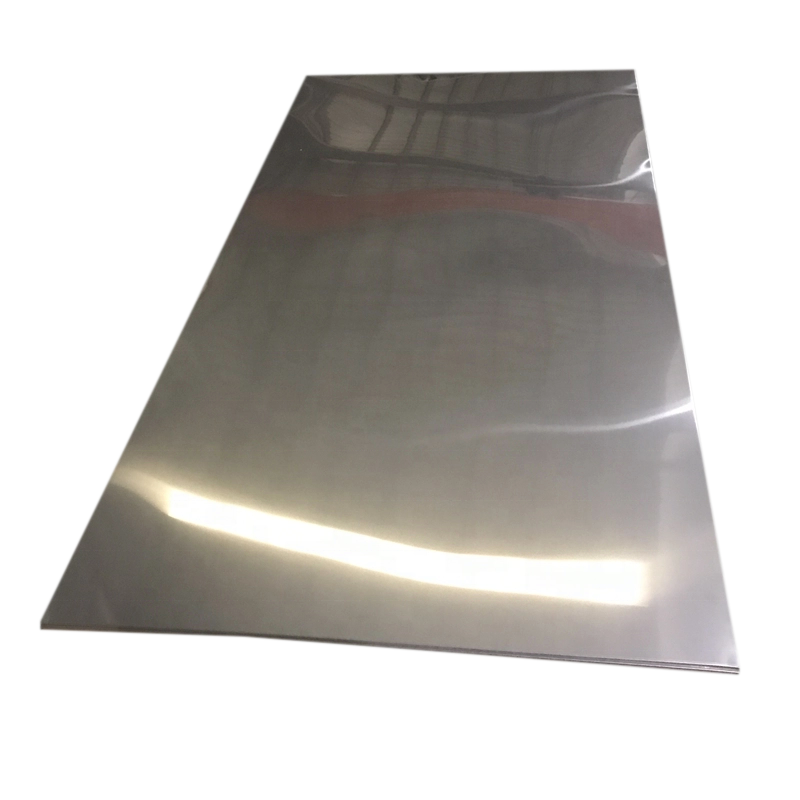

BA

Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc.

8K

The product have excellent brightness and prefer reflexivity can to be the mirror.

Packing: Standard export seaworthy packing.

Payment: T/T or L/C

Delivery time: 35days after receive the 30% deposit.

Port : Tianjin/Shanghai/Qingdao

Contact: Edwin

Company: Hannstar Industry Company Limited

Address:No.168, Yizhou road, Dongying, Shandong, China

Tel: +86-189-6300-9518 (whatsapp)

Fax: +86 - 546 -6064825

Mobile: +86-156-6667-1904 (wechat)

QUICK LINKS

CONTACT US

Dongying City, Shandong Province, China

+86-189-6300-9518

+86-189-6300-9518

HANNSTAREDWIN