| Availability: | |

|---|---|

| Quantity: | |

Product Description

DESCRIPTION

Alloy 52 is a 52% nickel-iron alloy developed for glass-to-metal seals for some of the soft glasses and some ceramics. Produced with good machining properties, it’s manufactured in a controlled environment under controlled conditions.

APPLICATION

Glass to metal seals for electronic tubes, automotive and industrial lamps, and specialty hermetic devices.

PARAMETER

Cross Reference:

Russia | USA | UK | Japan | France | Germany |

50H | FeNi50 | Nilo51 | NS-1 | N50 | Vacovit500 |

Typical chemistry:

C | P | S | Mn | Si | Al | Ni | Fe |

≤ | |||||||

0.05 | 0.020 | 0.020 | 0.80 | 0.30 | 0.10 | 49.0-50.5 | BAL |

Physical Property:

Heat Treatment System of the Samples | Average Coefficient of Linear Expansion | ||

20-300°C | 20-400°C | 20-500°C | |

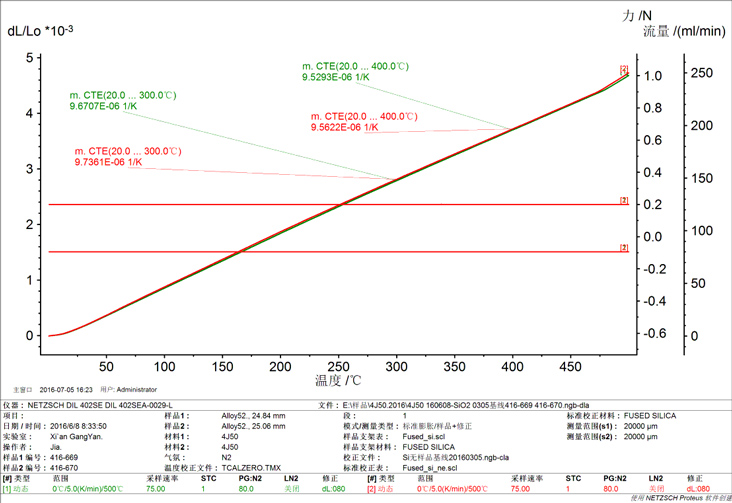

To be heat treated at a temperature of 900±20℃ the hydrogen, hold for 1h, cool at a rate less than 5℃/min to 200℃ | 9.2-10.0 | 9.2-9.9 | |

Mean coefficient of linear expansion at different temperature, ā/(10-6/K):

Mechanical Properties:

Elongation | % in 2 in. | 35 |

Typical Hardness Ann | Rockwell HRB | 80 |

Modules of Elasticity | ksi | 23 |

MPa | 159 | |

Yield Strength | ksi | 40 |

MPa | 276 | |

Tensile Strength | ksi | 80 |

MPa | 552 |

SIZE RANGE

Sheet | Thickness:0.10mm~3.50mm, width: ≤300mm |

Plate | Thickness:3.5mm~40.0mm, width: ≤500mm |

Round wire | Thickness:0.10mm~5.0mm |

Flat Wire | Dia 0.5mm~Dia 5.0mm, length≤1000 |

Rod | Dia 5.0mm~Dia 8.0mm, length≤2000 |

Dia 8.0mm~Dia 32.0mm, length≤2500 | |

Dia 32.0mm~Dia180.0mm, length≤1000 | |

Capillary | OD 8.0mm~1.0mm,ID 0.1~8.0 length≤2500 |

Pipe | OD 120mm~8.0mm,ID 8.0~129 length≤4000 |

Condition: (With max tolerance) cold rolled, cold drawn, hot rolled , hot forging ,peeled turned ,bright ,bright annealed

ADVANTAGES

1. HIGH-QULITY PRODUCT

· ISO9001:2008 International Quality System Certification.

· With advanced equipment’s: VIMF, Induction Furnace, ESR Furnace etc.

· Strict Quality-testing System.

2. STRONG R & D STRENGTH

· 40,000㎡ production base.

· 60+ R & D team members, with rich customization experience.

· A good assortment of alloy to choose.

3. EFFICIENT DELIVERY

· Flexible transport means, very convenient.

· Tailor a suitable transport plan.

4. GOOD SERVICE

· We provide online service, information feedback within 24 hours.

· Professional team to provide remote technical advice and guidance.

CONTACT

HANNSTAR INDUSTRY Co., Ltd.

TEL& WhatsApp: +86-189-6300-9158

WeChat: hannstaredwin

Email: hannstar@hannstarsteel.com

Add.: Dongying City, Shandong Province, China

content is empty!

QUICK LINKS

CONTACT US

Dongying City, Shandong Province, China

+86-189-6300-9518

+86-189-6300-9518

HANNSTAREDWIN